How Artificial Intelligence is enhancing the manufacturing industry: AI technology in China’s factories | Daxue Consulting

In 2016, the Chinese government made a commitment to its Three-Year Guidance for Internet Plus Artificial Intelligence Plan that would focus on funding and the development of AI, which will boost its economy. At a subsequent year, the State Council released a New Generation Artificial Intelligence Development Plan which contained details on China’s strategy to build a $150 billion national AI industry in the near future. With this plan, China is on its way to becoming the leading AI superpower by 2030. Considering AI development and proliferation, the Government focus on integrating AI technology in China’s factories to harness and adopt the practices of: Integrated intelligent systems, which includes networked vehicles, service robots, drones, video image identification systems, voice interaction system, smart sensors, neural network, and chips.

AI in China’s manufacturing industry is now finding its ground as the smart factory technology in China is advancing and costs drop, and as manufacturers discover applications for which AI algorithms can make complex decisions. And as it becomes ubiquitous, the future of AI technology in China’s factories already becoming feasible in emerging markets; showcasing better sensory capabilities; and, off the factory floor, predicting what will be needed and when.

Many medium and large manufacturers are starting to use data analytics to optimize factory operations, boosting equipment utilization, product quality while reducing energy consumption and production cost. With new supply-network management tools, factory operational managers have a clearer view of raw materials and manufactured parts flowing through a manufacturing network, which can help them schedule factory operations and product deliveries to cut costs and improve efficiency. Through the active use of data mining, engineers and technicians are gaining the new insight into a machine failure, so that to improve reliability. Smart, connected products are sending customer experience data to product managers to help them anticipate demand and maintenance needs and design better products.

General Concept and use of Artificial Intelligence in Chinese Factories

After the introduction of the New Generation Artificial Intelligence Development Plan, China became the new AI hub of the world. There was a tremendous increase in AI research institutes; the Government started funding AI start-ups, and Chinese companies are getting more investors from all corners of the world. The application of Artificial Intelligence in Chinese factories is more includes: the manufacturing process, product development, monitoring, logistics, and environmental safety.

The use of Artificial Intelligence in Chinese factories is classified be categorized into two sections; firstly,

- Production research and development. This can involve the use of Facial Recognition, Voice Recognition, Deep Learning, Machine Learning Natural Language, and Neural Network.

- The production process, improvement: This involves the use of Robot, monitors to an aide to ease the production process.

| S/No | Company | Application |

| 1 | DJI | Drones |

| 2 | Geek+ | Logistic Robot |

| 3 | Ubtech Robotics | Robotic |

| 4 | Sensetime | Face Recognition |

| 5 | Cambricon | Chips |

| 6 | Cloudwalk | Face Recognition |

| 7 | Siasun Robot | Automation and Robotics |

| 8 | Mobvoi | Voice Recognition |

| 9 | Horizon Robotics | Robotics |

| 10 | CloudMinds | Cloud Intelligent Robot |

| 11 | Canbot | Robotics |

| 12 | Roobo | Robotics |

| 13 | Xiaoyi | Robotics |

| 14 | Huanxin Robot | Robotics |

| 15 | NewWay Water Rock Technology | Robotics |

| 16 | Aqiu Technology | Robotics |

| 17 | Turning Robot | Robotics |

| 18 | Estun Automation | Robotics |

| 19 | Shanghai STEP Electric | Robotics |

| 20 | Hon Hai | Automation and Robotics |

| 21 | Megvii | Facial Recognition |

| 22 | Wangeng Technology | Robotics and Automation |

| 23 | Mor.AI | Voice Recognition |

Artificial Intelligence as the main catalyst for advancing Chinese factories: how AI has improved the productivity of smart factory technology in China

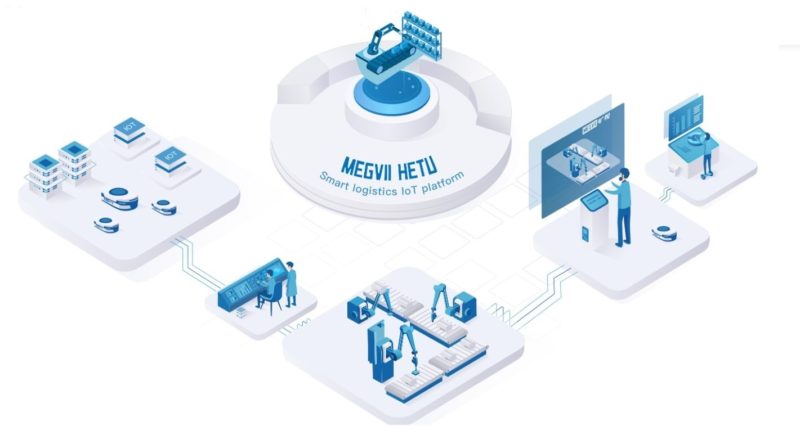

With an increase in demand from China’s consumers in the late 1990s and early 2000, most of the production companies begin to increase their production vehemently, minimizing their labor cost and maximizing the production capability. However, it’s inarguably fact that Artificial Intelligence in Chinese factories is the smartest, surest, and the precise way of achieving optimal productivity. MEGVII is a world-class AI company with core competencies in deep learning founded in Beijing and is a pioneer in applying AI technology and computer vision algorithms to the Internet of Things (IoT) use cases. The Company’s mission is to use innovative AI technology to deliver the value of AI in China’s manufacturing industry and foreign industries as a whole.

MEGVII’s first commercialized AI product was a facial recognition solution. The Company has developed its proprietary deep learning framework Brain++, which functions as a unified underlying architecture and provides critical support tailored for the Company’s algorithm training and model improvement processes.

Leveraging its strong software-hardware integration capabilities, MEGVII offers full-stack solutions to its customers and has achieved leading positions in several key vertical markets, including personal IoT, city IoT, and supply chain IoT. MEGVII is building an AI infrastructure to connect and empower various IoT devices, to solve real-life problems, pain points, and hitches that may hinder the success of AI in China’s factories. MEGVII is dedicated to helping customers achieve specific goals such as user authentication and fraud reduction, traffic optimization, and labor efficiency gains.

AI technology in China’s factories

AI in China’s manufacturing industries through the use of deep learning algorithm has yielded to an inconsistency industrial profitability and reducing production cost. Changying Precision Technology Co., Ltd. Changying Precision” is a research and development, production and sales of intelligent terminal, mobile phone components, new energy automotive components, industrial robots, and automation system integration. AI Presently, Changying Precision has approximately 35,000 employees and has a global presence. The compound revenue growth rate of 2010-2017 is over 50%, and the compound profit growth rate of net profit attributable to shareholders of listed companies exceeds 40%. In 2017, the company’s operating income exceeded 8.4 billion yuan, and its net profit was 571 million yuan.

AI in China’s manufacturing industry: Foxconn

As a leading technological solution provider and the largest producer of mobile phone component of the giant Apple, Foxconn Group has fully leveraged its expertise in software and hardware to integrate its unique manufacturing prowess with emerging technologies. Its expertise in the area of cloud Computing, Mobile Devices, IoT, Big Data, AI, Smart Networks and Robotics/Automation, the Group has expanded capabilities in four key technologies – Data Tech, Analytics Tech, Platform Tech, Operations Tech. Foxconn achieved NT$ 5.2 trillion in revenue and received an array of international accolades and recognitions: Foxconn Technology Group was ranked 24th among Fortune Global 100, 105th among Forbes Global 2000, 8th among Forbes Top Multinational Performers, and 215th among Forbes World’s Best Employers. Foxconn has invested in more than 40 production bases in mainland China, by the end of 2017, it had applied for 54,600 patents and approved 29,900 patents in mainland China and Foxconn. There were 146,200 patent applications and 83,600 patent applications in various parts of the world. In mainland China, the average annual export volume was 3.9%, and the accumulated foreign exchange earned US$237.4 billion.

Facial Recognition algorithms have become a competitive advantage for China’s factories

Due to the rapid development of information technology, computer science, and advanced manufacturing technology in China, manufacturing production has been changing from automated production to digitalized and intelligent production. SenseTime is one of the biggest unicorns in China which specializes in deep learning and computer vision technologies. In the field of automotive, they have provides a German automotive car manufacturing factory (Daimler) with a public face cloud service for face recognition, using authentication technology to help business development in the area such as Mercedes-Benz Finance and shared cars e.t.c. Also, they have signed a long-term cooperation agreement for five years, jointly deepening the autonomous driving technology, accelerating the research and development of smart cars, and jointly developing an L4-level automatic driving solution suitable for passenger car scenes. SenseTime has enhanced the use of AI in China’s factories, having over 700 partners and customers, the company valued over US$4.5 billion after raising US$620 million in Series C+ funding, maintaining its position as the world’s largest and most valuable AI unicorn.

Artificial Intelligence In Chinese Factories using Natural Language

Manufacturing technology in China has witnessed a drastic improvement from the 1990s to date. Xiaoyi is a leading artificial intelligence technology company, focusing on independent research and development and industrial application of cognitive intelligence. Based on multi-language natural language processing, deep semantic interaction, speech recognition, and machine learning and other artificial intelligence core technologies, it has formed diversified solutions and perfect professional service systems of AI in China’s factories.

As a pioneer in the application of artificial intelligence industry, Xiaoyi covers the business of “smart +” customer service, “smart +” city and “smart +” hardware to finance, medical, education, automobile, electric power, manufacturing, and exhibition. Geographically, Xiaoyi established an Asia-Pacific center in Hong Kong to support multilingual interactions such as China, Britain, and Guangdong, and its business has expanded overseas. With more than ten years of project practice and hundreds of billions of human-computer interactions, Xiaoyi has precipitated a large-scale domain semantic library and industry knowledge base in various industries and fields.

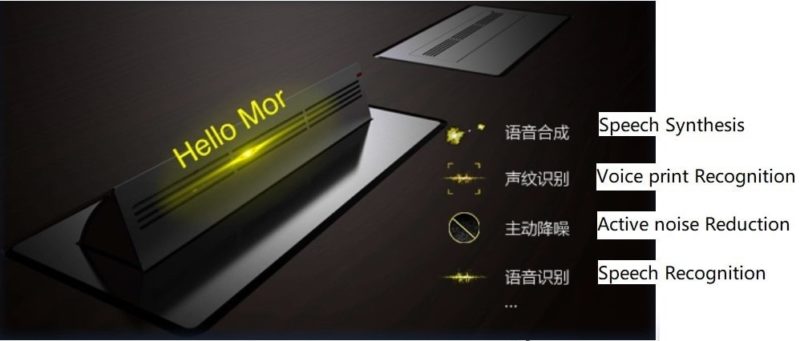

Artificial Intelligence In Chinese Factories using Voice Recognition

The use of Artificial Intelligence in Chinese factories has broad application, Mor.AI focus on cognitive computing, natural language understanding, with autonomous voice interactive full-stack technology (noise reduction + speech + semantic + multi-round dialogue + knowledge map). Based on the dialogue platform, through the construction of the APP-based dialogue application, the voice interaction mode is used as the axis, and the multi-modal interaction mode is integrated to distribute the service, so that the device has the anthropomorphic interaction ability, construct the interactive AIOT network, and perform the scene.

In the automotive industry, it can provide the vehicle voice assistant, which supports multi-modal interaction, multi-screen interaction, multi-device collaboration, car home interconnection, IMOV car networking overall solution.

The company became the won in the field of C interconnection in [2018 BMW open innovation], acquiring A+ round of financing 10 million US dollars, also received 36 [2018 New Economic king of “Artificial Intelligence Voice Award”]. Its application in car automobile industry includes:

- Car conversation application

- Car Voice Processing (MorVoice)

- Car networking platform

- Special function

The key success of AI in China’s factories for product and production efficiency

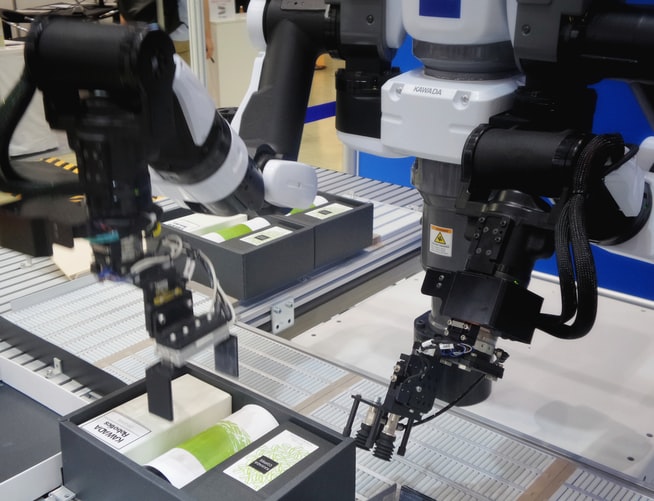

Robot companies contribute to the development of Artificial Intelligence in Chinese factories. The Chinese robot market is forecast to grow at an average annual rate of 23.4 percent in the four years to 2019, much faster than global shipment growth of 13 percent, according to the International Federation of Robotics. China’s robot makers aim to supply 50 percent of the domestic market by 2020, rising to 70 percent by 2025. Chinese industrial robot producers had performed remarkably well in 2018. In the same year, ESTUN earned the revenue of RMB735 million from industrial robots and intelligent manufacturing technology in China, an upsurge of 50.28% over last year, and with an anticipated growth rate of 20% in 2019. Brotherobot outperformed its goal by selling 15,788 manipulators and 5,137 robots (compared with only 351 units in 2017) and ranked first in China by the sales volume of robots made in China.

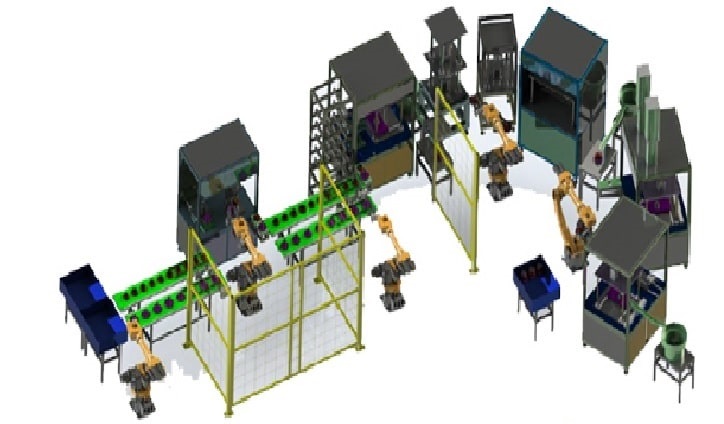

Shanghai STEP Electric Corp.

Is a small company that provides industrial robots along with control systems and software for industries like welding, packaging, construction, and machining. It has a market cap of just $870 million.

SIASUN Robot & Automation Co. Ltd

SIASUN manufactures sells industrial robots such as automatic assembly and testing production lines for automobile, motorcycle, engineering machinery, and electronics assembly industries. Besides heavy industry applications, Siasun developed collaborative robots that can work with humans, an underground rescue robot as well as humanoid helpers for interpretation, meal delivery, information sharing, and nursing homes. The company has a partnership with GM Motors, Ford, AGCO Changzhou, Great wall motor, SANDISK, and Geely auto; it currently has a market cap of $4.23 billion.

Use of AI in China’s factories for production and distribution

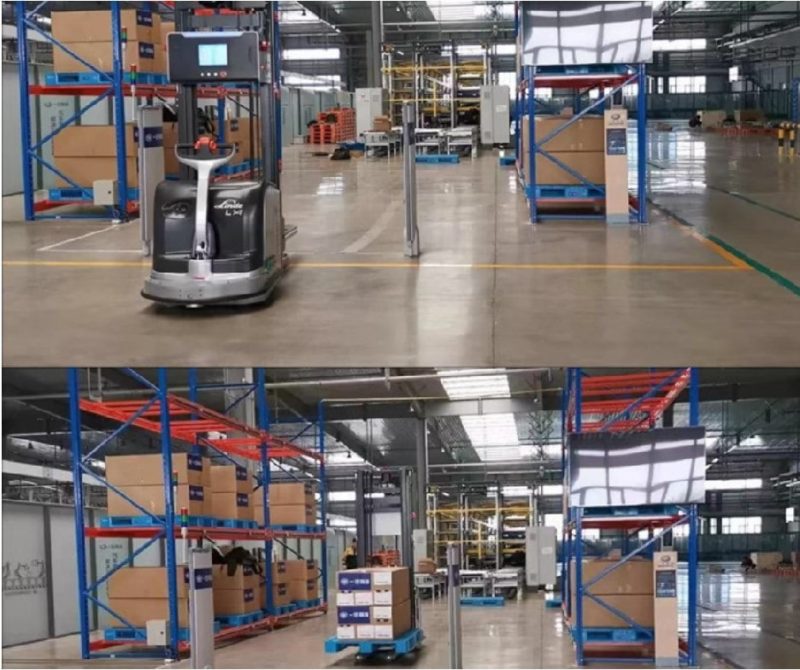

Considering an increase in production, AI in China’s manufacturing industry has recorded an unprecedented success in Logistics and Warehousing. Geek+ leads the technology revolution by applying advanced robotics and AI technologies to realize high-flexibility and intelligent logistics automation solution. Geek+ provides leading, reliable, one-stop enterprise-level service with strong technological strength.

With much solid research and practice experience in the fields of the robot, embedded development, software engineering, artificial intelligence, many of them have joined domestic/and international robotic contests and won the championship. All products are developed independently and possess the core patents, with a world-class level performance. FAW Group, a state-owned automobile enterprise with a yearly output of 3 million vehicles, has built up a research center for intelligent logistics technologies. As a world-class AI & Robotics solution provider, Geek+ has joined the FAW Logistics Lab. Its automated forklift has been applied in the automatic logistics system of FAW Changchun HQ factory. Geek+ also has a partnership with: DKSH Pharmaceutical, ACCA E-Commerce company in Japan, SF Express, Lianhua, Suning, Fiser logistics technology, VIP.com, and Tmall. Geek+ has delivered more than 5,000 robots across some 100 robotics warehouse projects in China, Hong Kong, Taiwan, Japan, Australia, Singapore, Europe, and the United States.

Artificial Intelligence in Chinese Factories is accelerating economic development, and China’sglobal competitional power

With its biggest tech companies driving momentum for R&D, China is one of the leading global hubs of AI development. Its vast population and diverse industry mix have the potential to generate huge volumes of data and provide an enormous market. The wide adoption of AI technologies in China’s factories could be crucial to future economic growth as the nation’s population ages, heightening the need to accelerate productivity growth. Some of the required building blocks include a more open data environment and well-trained data science talent. But AI also poses complex social and economic questions that will require careful consideration.

China is currently leading the world of AI in terms of funding, research, and talent. However, data seems to be the fuel of AI, and China has the highest number of internet users on earth. According to Irakli Beridze (2019), Head of the Centre for Artificial Intelligence and Robotics, United Nations, said that “China’s biggest strength is that the government, private sector, and academia are working hand-in-hand to achieve this national AI goal. He further expands on this, stating that China is currently the world’s second-largest economy, and one of the first countries to announce a national AI strategy, which they did in 2016.

Author: Abdulhamid Sillah

Want to learn more about AI in China? Check out our AI in China White Paper.